Certified Company

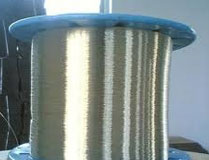

0.5mm ZR5668 Wire Material Specification

| Weight in meter | ≈1.31g/m |

| Quantity | 1meter |

| Odor | Odorless |

| Physical Form | Wires, ≈1.31g/meter |

| Purity in Percent | 99.2% |

| Chemical Material | Zr wires, 0.5milimeter (0.020 inch) dia., Annealed |

| Assay | (metals basis excluding Hf) Hf 4.5% max |

| Zirconium Material Chart | ERZr2, ERZr4, ERZr3, high purity zirconium |

| Size Chart | 0.3-6.0milimeter diameter x L |

| Specification | ASTM B550, 550M-07, AWS A5.24 |

ERZr2 Zirconium Copper Wire, UNS R60702 Zirconium tig Wire, Zirconium Welding Rods Wires Manufacturer in India

Zirconium Wire Mesh Chemical Structure

| Grade Chart | Sn | H | N | Zr+Hf | Hf | Fe+Cr | C | O | Nb |

| R60702/ERZr2 | - | <0.005% | <0.015% | 99.2% | <4.5% | <0.20% | <0.030% | <0.15% | - |

| R60704/ERZr3 | 97.5% | <4.5% | 0.2-0.4% | 1.0-2.0% | <0.005% | <0.015% | <0.030% | <0.16% | - |

| R60705/ERZr4 | 95.5% | <4.5% | <0.2% | - | <0.005% | <0.015% | <0.050% | <0.16% | 2.0-3.0% |

Zirconium Welding Wire Mechanical Properties Table

| DESIGNATION | TENSILE STRENGTH | YIELD STRENGTH 2% OFFSET |

PERCENT ELONGATION |

||

|---|---|---|---|---|---|

| KSI* | MPa** | KSI* | MPa** | ||

| Annealed (A) | 35 | 241 | 10 | 68 | 55 |

| Half Hard (1/2H) | 62 | 427 | 53 | 365 | 11 |

| Hard (H) | 68 | 468 | 60 | 413 | 10 |

| Extra Hard (XH) | 70 | 482 | 62 | 427 | 10.5 |

| Spring | 72 | 496 | 63 | 434 | 11 |

ERZr2 Zr Copper Wire Size Chart In Mm

| Dia in mm | Diameter in mm | Dia in inches |

|---|---|---|

| 1.14 | 1.2 mm | 0.045 |

| 1.57 | 1.6 mm | 0.03 |

| 2.3 | 2 mm | 0.04 |

| 3.175 | 3.15 mm | 0.047 |

PED Approved UNS ZR0929 Zirconium Wire Weight Chart, Zr702 Zr700 pure zirconium coiled wire, Check ASTM B550 zirconium 702 wire properties

UNS R60702 Zirconium tig Wire Physical Composition

| Melting Point | 1795 to 1975°F | 980 to 1080°C |

| Density | .321 lb/cu inch @ 68°F | 8.89 gm/centimeter@ 20°Celcius |

| Specific Gravity | 8.89 | 8.89 |

| Coefficient of Thermal Expansion | .000094 per °Farenheit (68-572°F) | .000017 per °Celcius (20-300°C) |

| Thermal Conductivity Chart | 212 BTU/sq ft/ft/hr/°Farenheit @ 68°F | .876 cal/sq cm/cm/sec/°Celcius @ 20°C |

| Electrical Resistivity (Aged) | 11.2 Ohms circ mil per ft @ 68°Farenheit | 1.86 microhm – cm @ 20°Celcius |

| Electrical Conductivity (Aged)† | 93% Copper IACS @ 68°F | .538 megohm cm @ 20°C |

| Specific Heat Treatment | .092 BTU/lb/°F @ 68°F | .092 cal/gm/°C @ 20°C |

| Modulus of Elasticity (tension) | 18,700 KSI | 13,000 kg/sq mm |

| Modulus of Rigidity in mm | 7300 KSI | 5000 kg/sq mm |

| Annealing Temperature †† in Celcius | 1600-1700°F | 870-970°C |

| Aging Temperature Annealed Hard |

930-1020°F (1-4 hr.) 700-890°F (1-4 hr.) |

500-550°C (1-4 hr.) 370-475°C (1-4 hr.) |